Lining

The first step of a refracturing job is to isolate the previously perforated casing.

Through our partnership with NewGen Systems, Nine offers its suite of REGEN™ Refrac Liner Systems that can be customized for your production needs.

Reliable functionality for subsequent operations

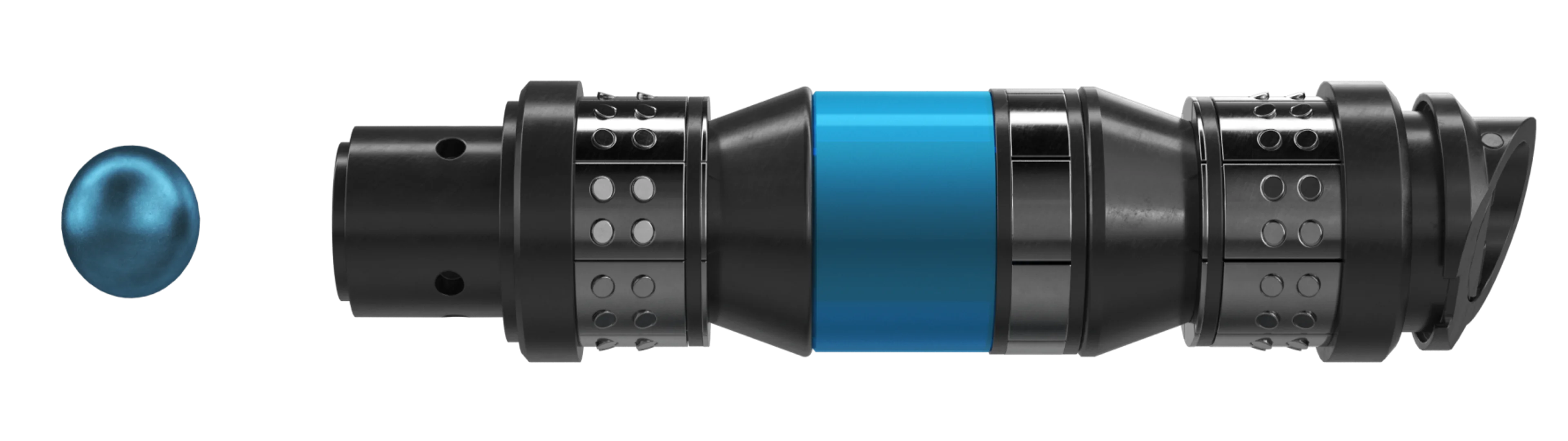

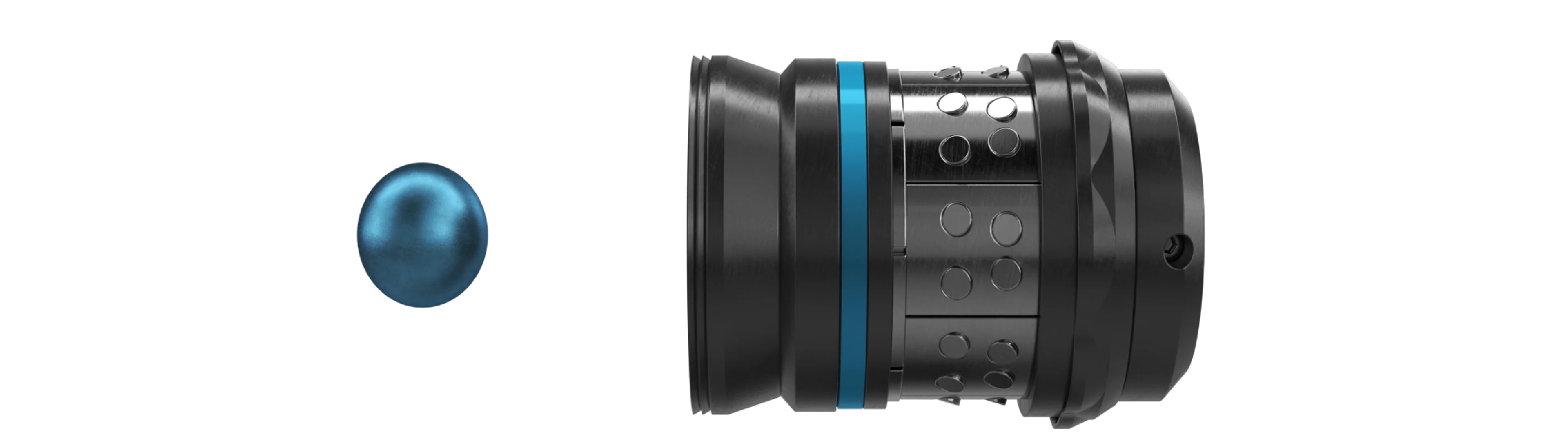

The REGEN™ Dual Ball Seat Sub (DBSS) uses two independent and redundant ball seats that can be configured for various ball and shear pressures, allowing for the operation of a range of hydraulic set tools.

Features Include:

- Hydraulic set

- Operationally simple and robust

- Optionally match OD and drift of liner

- Rotationally locked internals

- Multiple ball seat size options

- Integral redundancy

- Integral latched landing sub

- Component of the REGEN™ Liner Hanger System

Streamlined Well Completion for Enhanced Efficiency

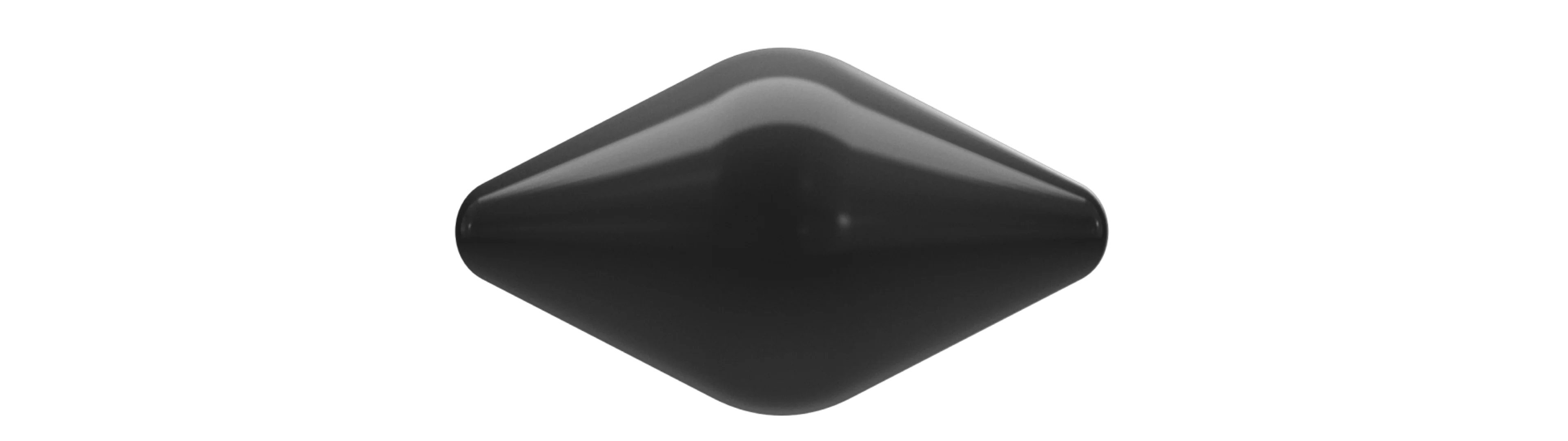

The REGEN™ Wet Shoe Sub (WSS) is part of the REGEN™ Liner Hanger System, designed to eliminate the need for cleanout trips or coiled tubing during well completion.

Features include:

- Hydraulic set

- Integrated landing profile

- Slim run-in-hole OD

- Short length

- Operationally simple and robust

- Interchangeable wiper dart seat insert

- Available in custom sizes

Versatile HPHT Solution for Recompletion Success

The REGEN™ Refrac Packer is engineered to withstand the highest pressure differentials, making it a versatile solution for recompleting existing wells.

Features Include:

- High-pressure capability

- Zero-extrusion gap design

- Slim run-in-hole OD

- Short length

- Field-proven technology

- Can be used in conjunction with the REGEN™ Liner Hanger

- Multiple applications

- Available in custom sizes

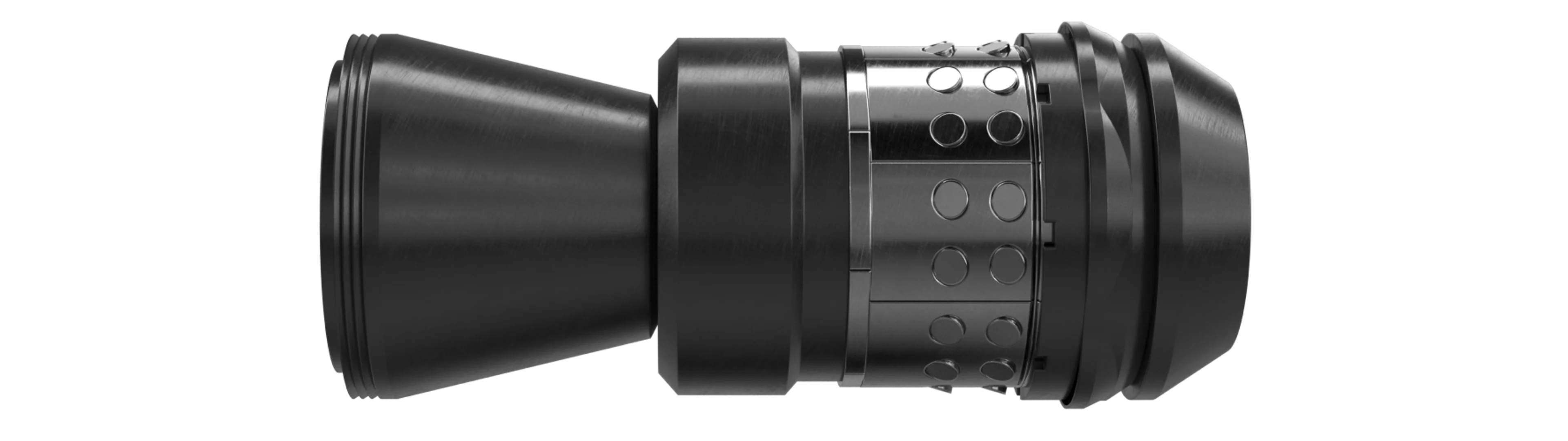

Efficient Well Restimulation with Simplified Operations

The REGEN™ Liner Hanger simplifies well restimulation while maximizing pump rates, effective for both cemented and uncemented applications.

Features Include:

- Hydraulic set

- Operationally simple and robust

- Slim run-in-hole OD

- Short length

- Proprietary slip design

- Anti-preset system

- Premium internal seals

- Matches liner drift

- Available in multiple sizes

Dependable Seal Integrity for Challenging Refracs

The REGEN™ Fullbore Liner Top Packer (FLTP) is an industry-leading solution for repairing refrac liner lap leaks in high-pressure, high-temperature environments.

Features Include:

- High-performance sealing

- No cement squeeze required

- Metal-to-metal reinforcement

- Customized elastomeric protection

- Slim run-in-hole OD

- Compact design

- Available in multiple sizes

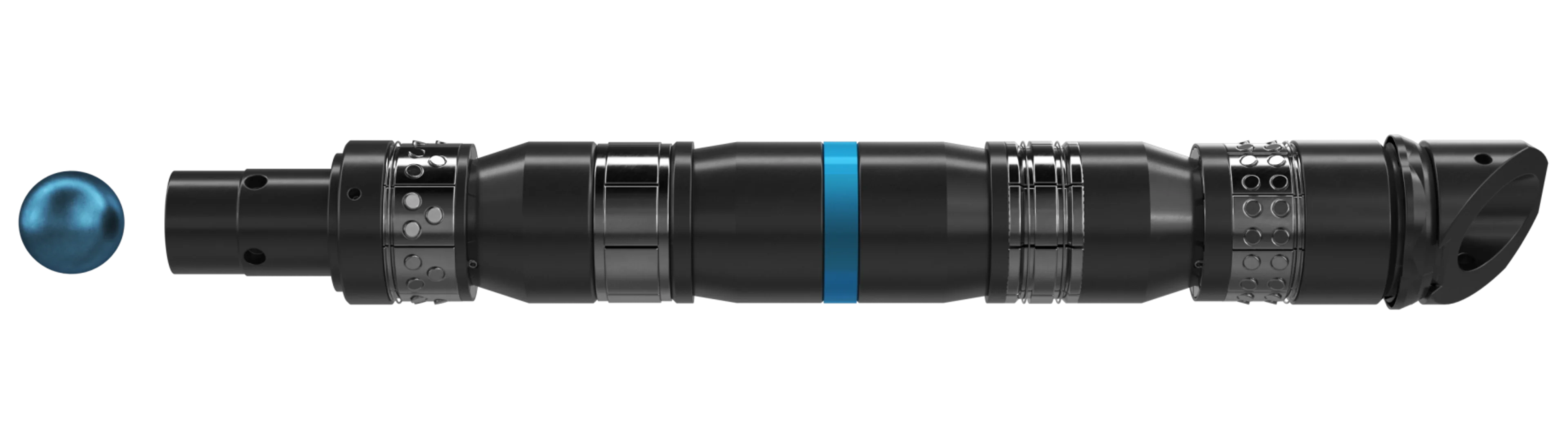

Robust Wellbore Integrity for High-Pressure Refracs

The REGEN™ Fullbore Liner Tieback System (FLTS) maintains wellbore integrity in recompletion operations, enabling operators to run full-size frac plugs and pump at high pressures.

Features Include:

- Slim run-in-hole OD

- Proprietary HPHT seals

- Single piece mandrels

- Fullbore ID

- Compatible with REGEN™ Liner Hanger System

- Available in multiple sizes

- Expertise in specialized perforation charges designed for liners.

- Smaller OD plug and play gun system and setting tool options.

- Caliper logging.

- Small OD Cement Bond Logging.

- Expertise in pumping down guns and plug in liners.

Cementing

A specialized combination of additives that resists gas and water invasion

A versatile, advanced polymer additive for maintaining slurry stability and fluid properties

A low-density slurry for low fracture gradients

An innovative, single-stage solution for overcoming isolation challenges in complex wells

A reliable system to reduce cement losses and formation damage

An efficient fluid system used in oil well remediation

Frac Isolation

Perforation

DetonationFor any well condition, Nine combines the latest equipment with wireline expertise to deploy customized charges for downhole detonation.

Delivering 180° visibility, SkyView empowers safer and faster pumping compared to traditional wireline trucks. Its dual power packs provide both hydraulic and electric power for reliable performance, while a built-in backup ensures continuous operation if one power source is compromised, maximizing productivity on every job.

Featuring cloud connectivity, it provides access to operations in real-time for immediate process improvements and maximum productivity.

Finally, our coiled tubing team is ready for cleanouts or scale removal, along with the perforation phase of your refrac, running up to 28,000 feet of 2 3/8-inch coil.

With AllSight, you can electronically track, evaluate, and manage every aspect of your coiled tubing job with real-time and historical data.

Nine's coiled tubing teams are as fast as they come. Which means you're not waiting around for your well to become productive and profitable.

- Frac plug millout

- Wellbore cleanout

- Fluid pumping

- Nitrogen pumping and bulk nitrogen delivery/sales

- Tubing-conveyed perforating (jet or abrasive)

- Fishing/milling

- Stimulation via coiled tubing

- Crane services

- Pre-job engineering, planning, and design with industry-leading software