Experience that runs as deep as your well

Zero to maximum ROI, without the operational speed bumps

At Nine, we implement the idea of interventionless completions. And with our comprehensive solutions for zonal isolation, pressure control and well construction, you can rest assured that you are on the shortest and fastest path to proven, cost-efficient performance with reliable production returns.

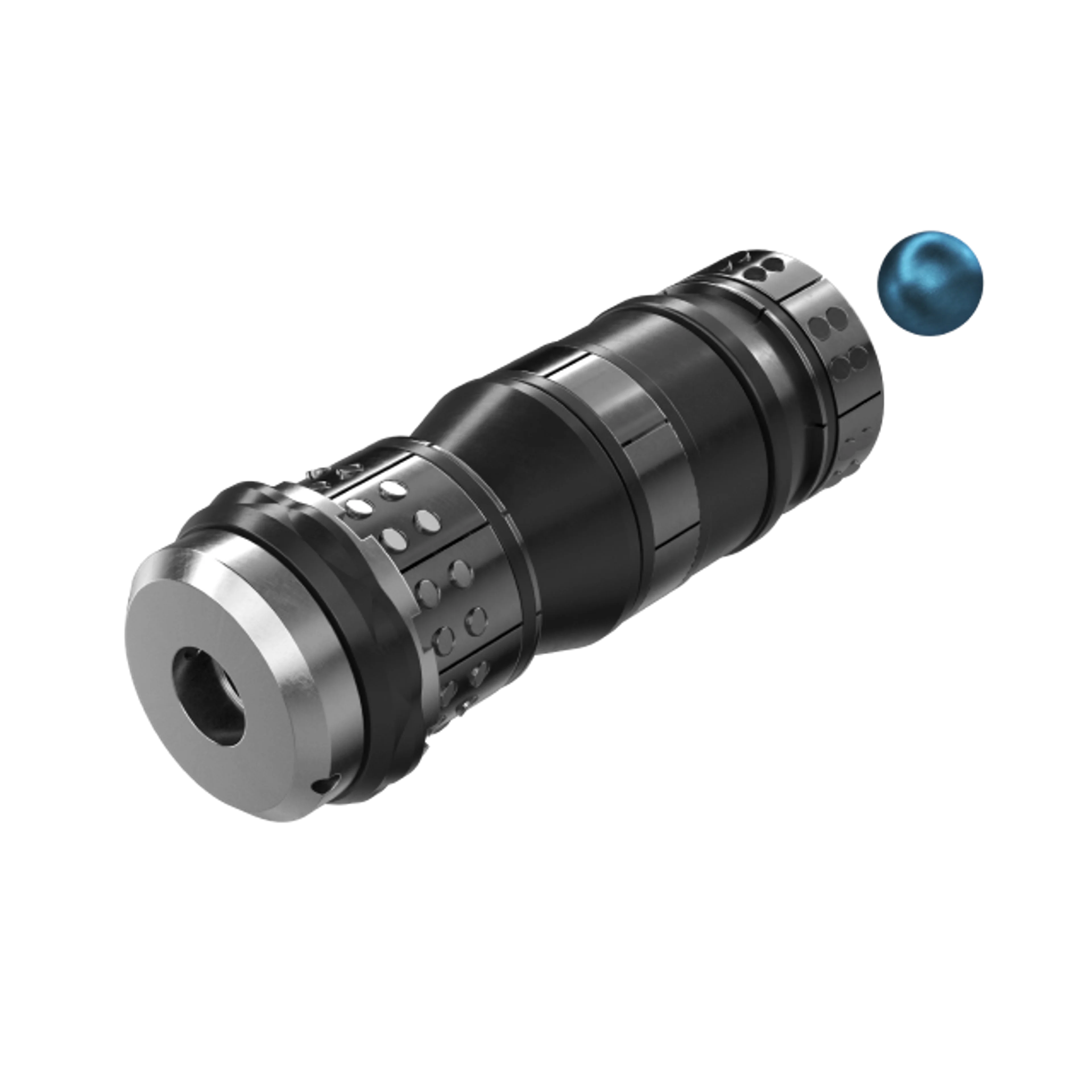

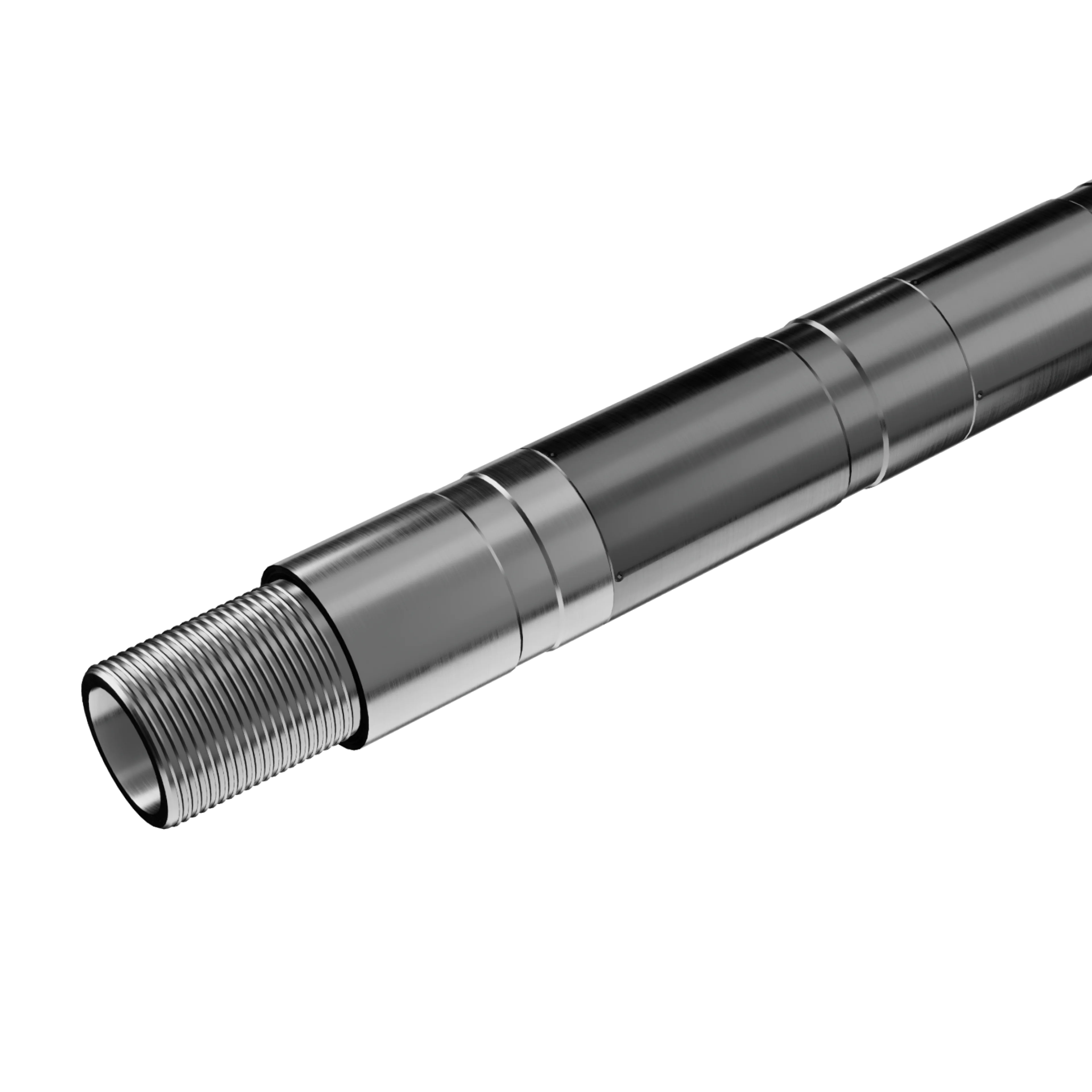

Frac Plugs

Zonal isolation: any well, anywhere

Whatever the job, it pays to bring the right tools. Nine’s comprehensive range of frac plugs can tackle any challenge, from long laterals to carbon-emission reduction.

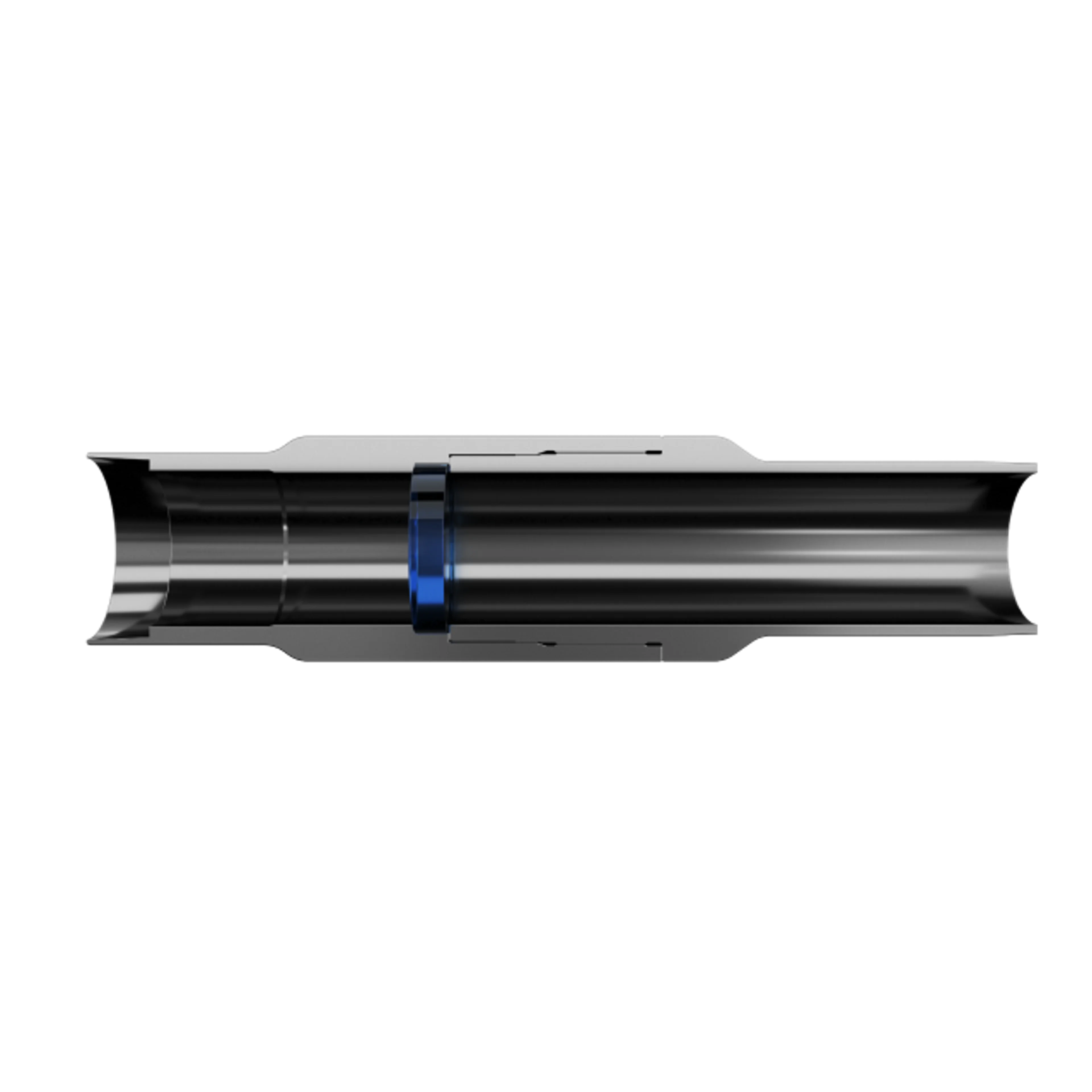

Refrac Liner systems

Reduce well-construction costs and risks

Through collaboration with NewGen Systems Ltd., Nine's refrac tools are customized and field-proven. These high-performance completion tools help you tap into previously stranded reserves and restimulate existing wells.

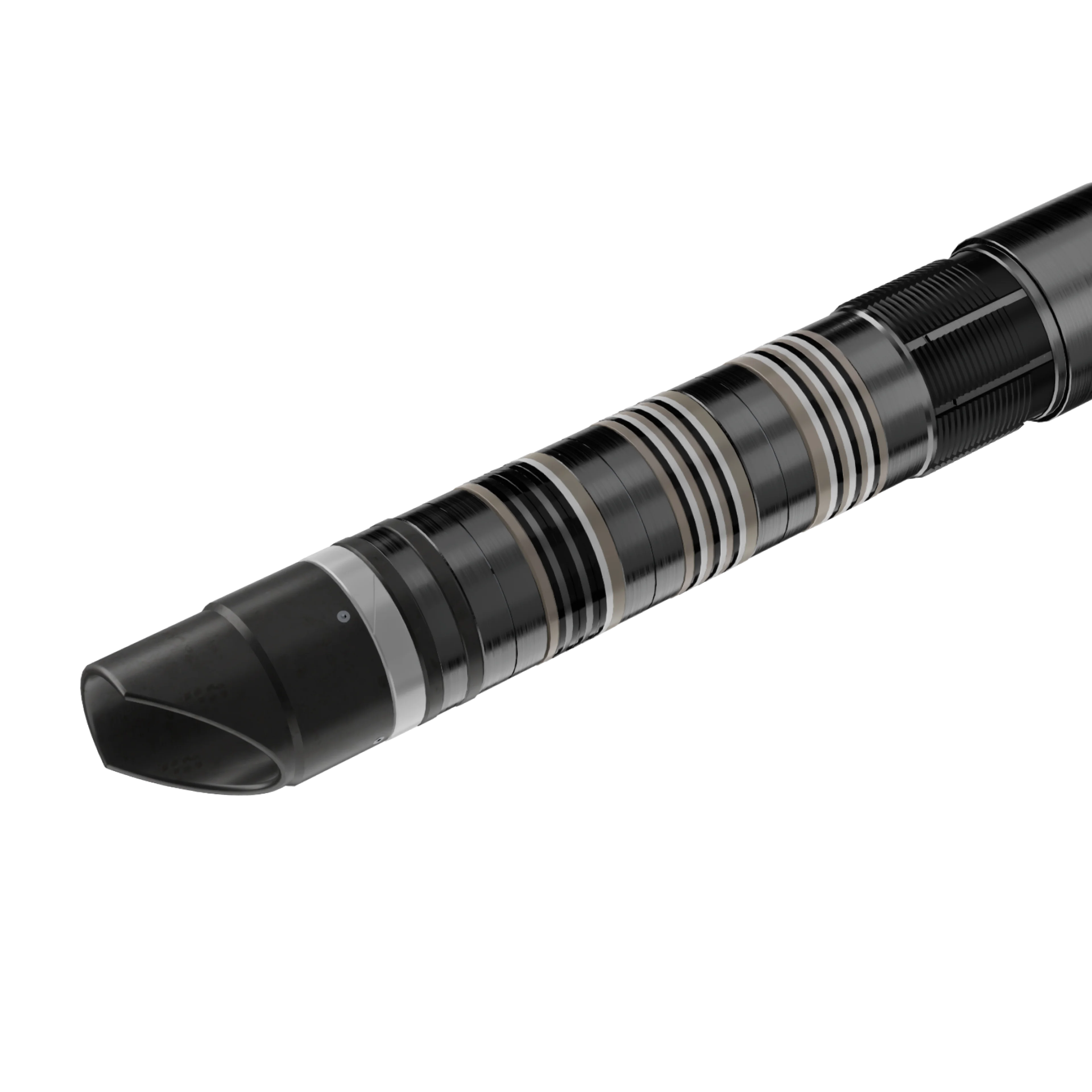

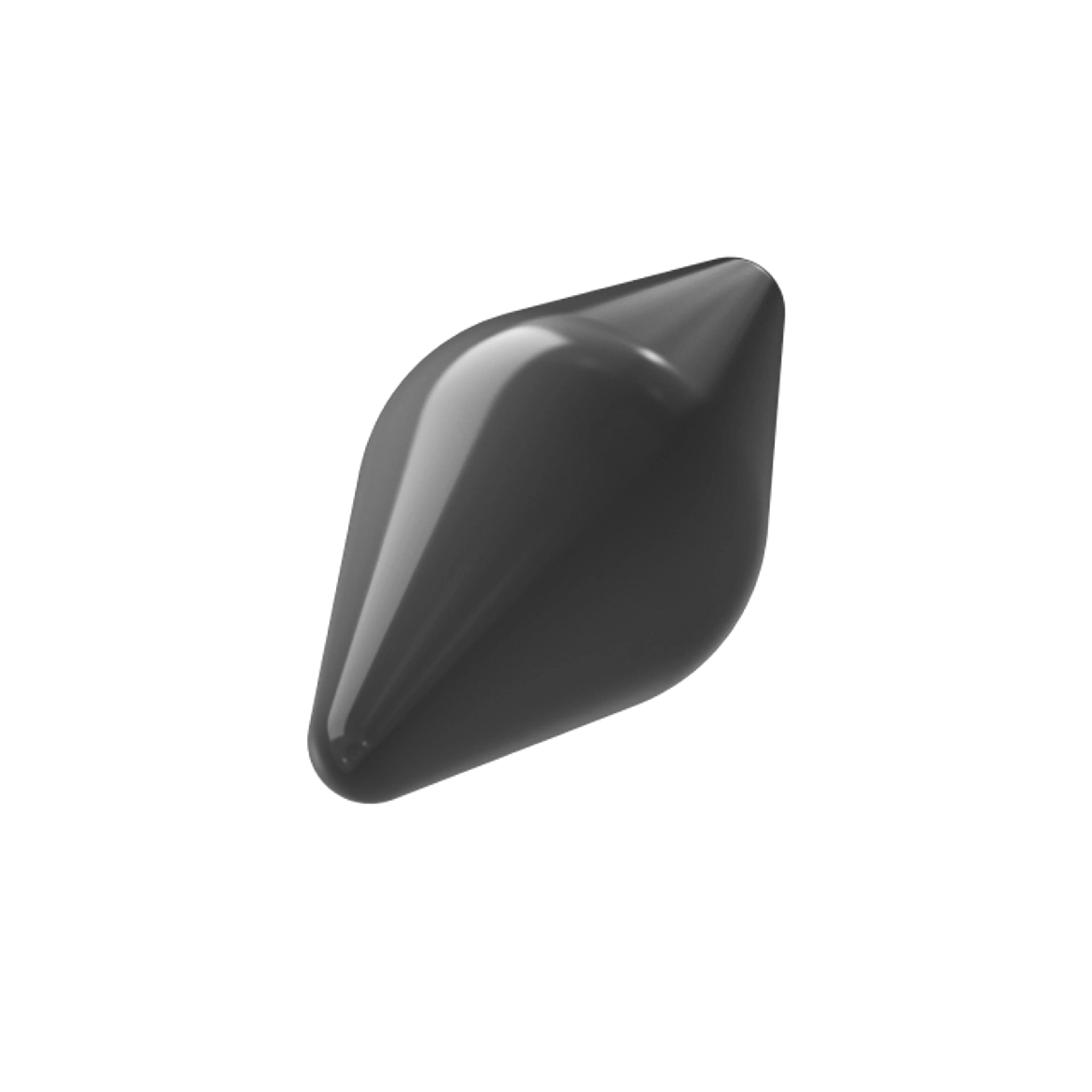

Flotation Devices

Take casing all the way to TD

To help ensure the success of your cementing job, this technologically advanced barrier delivers the buoyancy to float casing across the longest lateral runs.

BreakThru™ Benefits

Withstands up to 10,000 psi

Easy removal by wireline or milling

Can be run in H2S or CO2

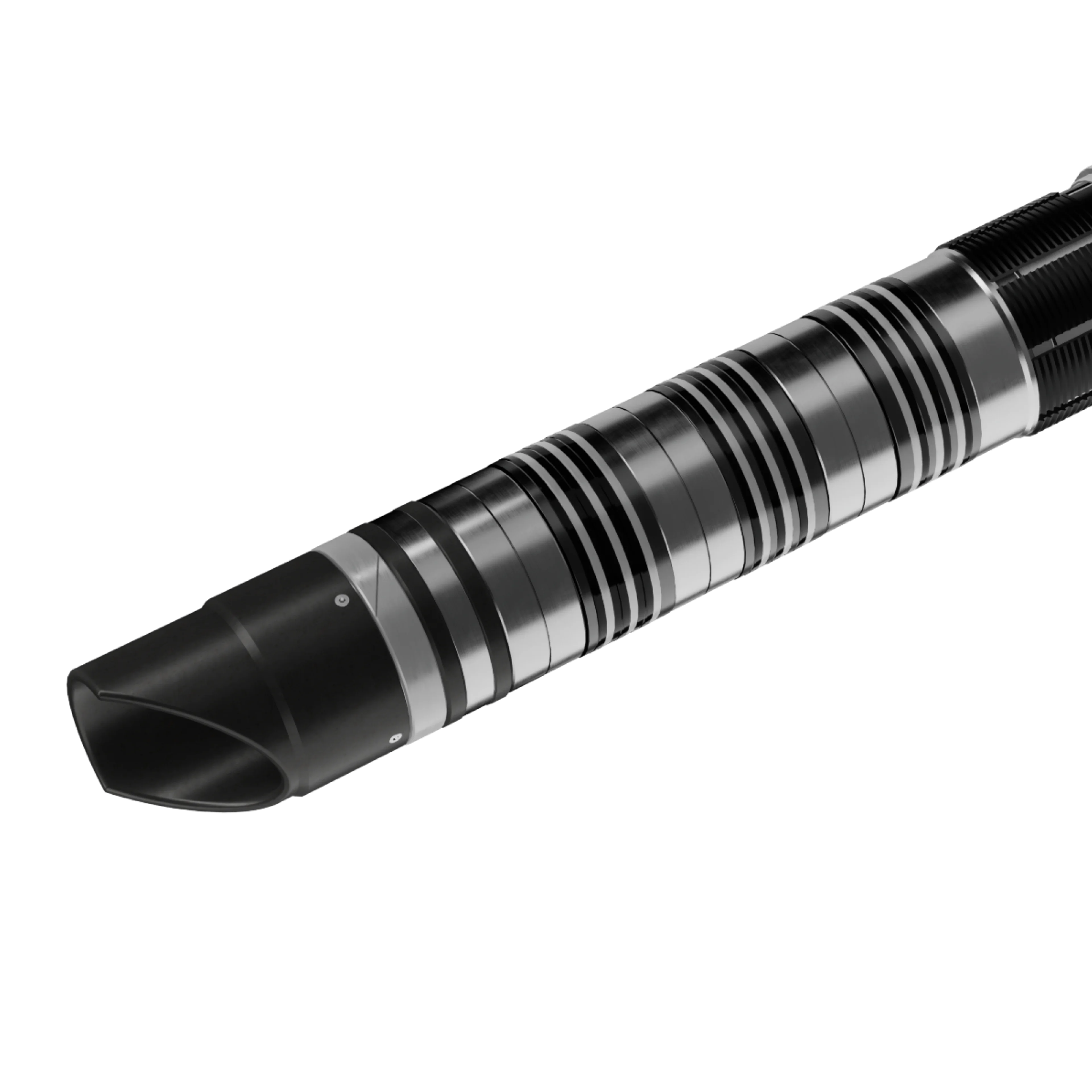

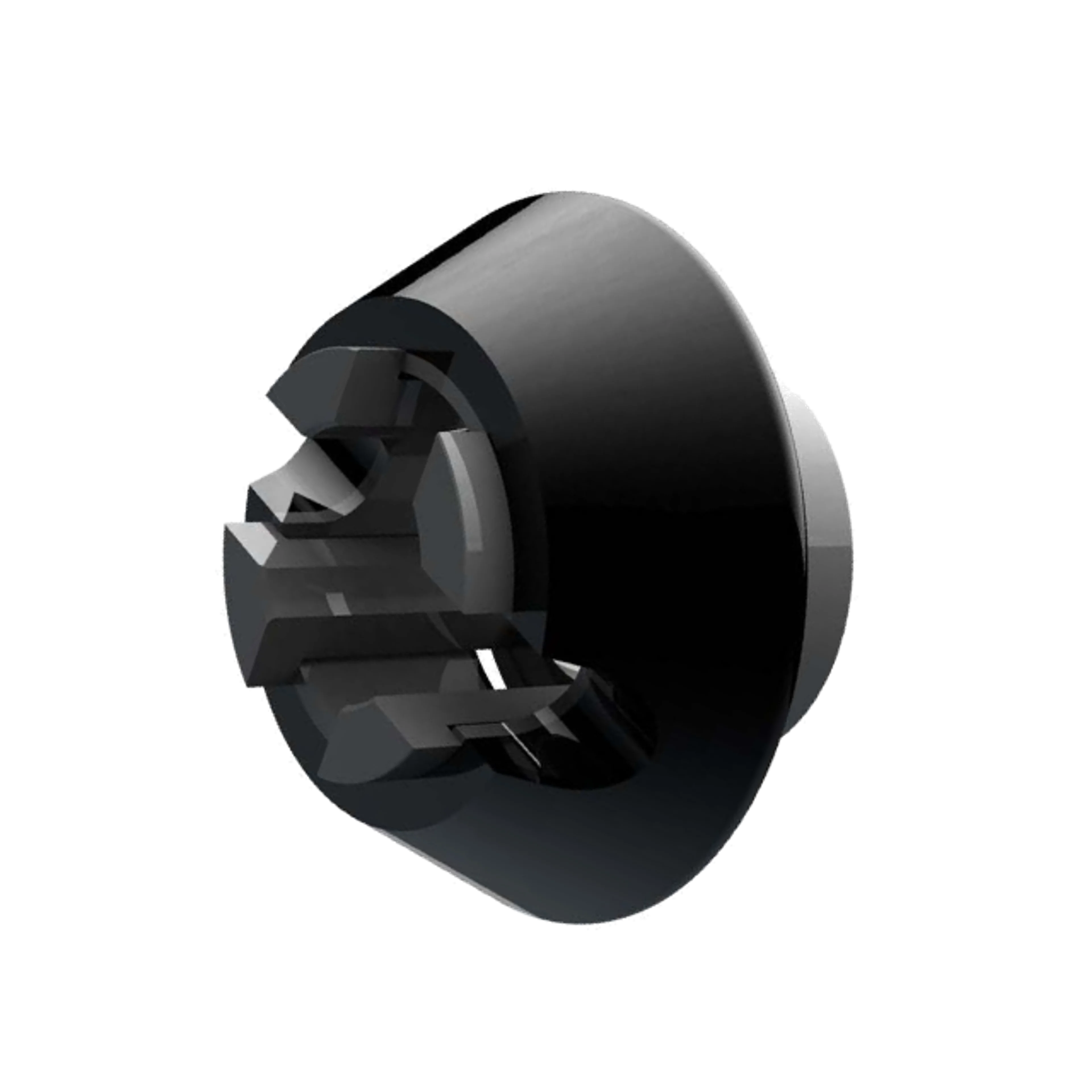

BreakThru™ glass Barriers

Precision solutions for every well

Designed to perform under the toughest conditions, Nine's BreakThru™ Barrier Device series - Intervention Actuated, Multi-Cycle, and Pump Open - delivers high-performance isolation and pressure actuation to optimize well completions and boost operational reliability.

BreakThru™ Benefits

Three variations

Can be run in H2S or CO2

Maximize efficiency

Ceramic disk Barriers

Versatile solutions. Proven results.

Effective in a variety of downhole conditions, our patented tubing disks are engineered to perform, boosting operational efficiency and ROI.

Toe Sleeves

At Nine, we believe in consolidation as a means to simplify your completions, cutting costs and improving safety in the process.

Composite cEMENT RETAINERS

Seamless cement retention

From interventionless designs to robust sliding sleeves, our CCR lineup sets the standard for efficient, reliable cementing.

Packers

Fast. Compatible. Incomparable.

You have a unique list of operational requirements for zonal isolation, pumping, and production. We have the production packers to accommodate any and all.

Perf Frac Diverter

Redirect fluids. Not profits.

Optimize your mid-stage diversions and refracs with this strategic fluid distribution solution that refocuses pressure for maximum production returns

Take control of your frac paths

Focus pressure where you need it

Fully Dissolvable

10,000 psi rated

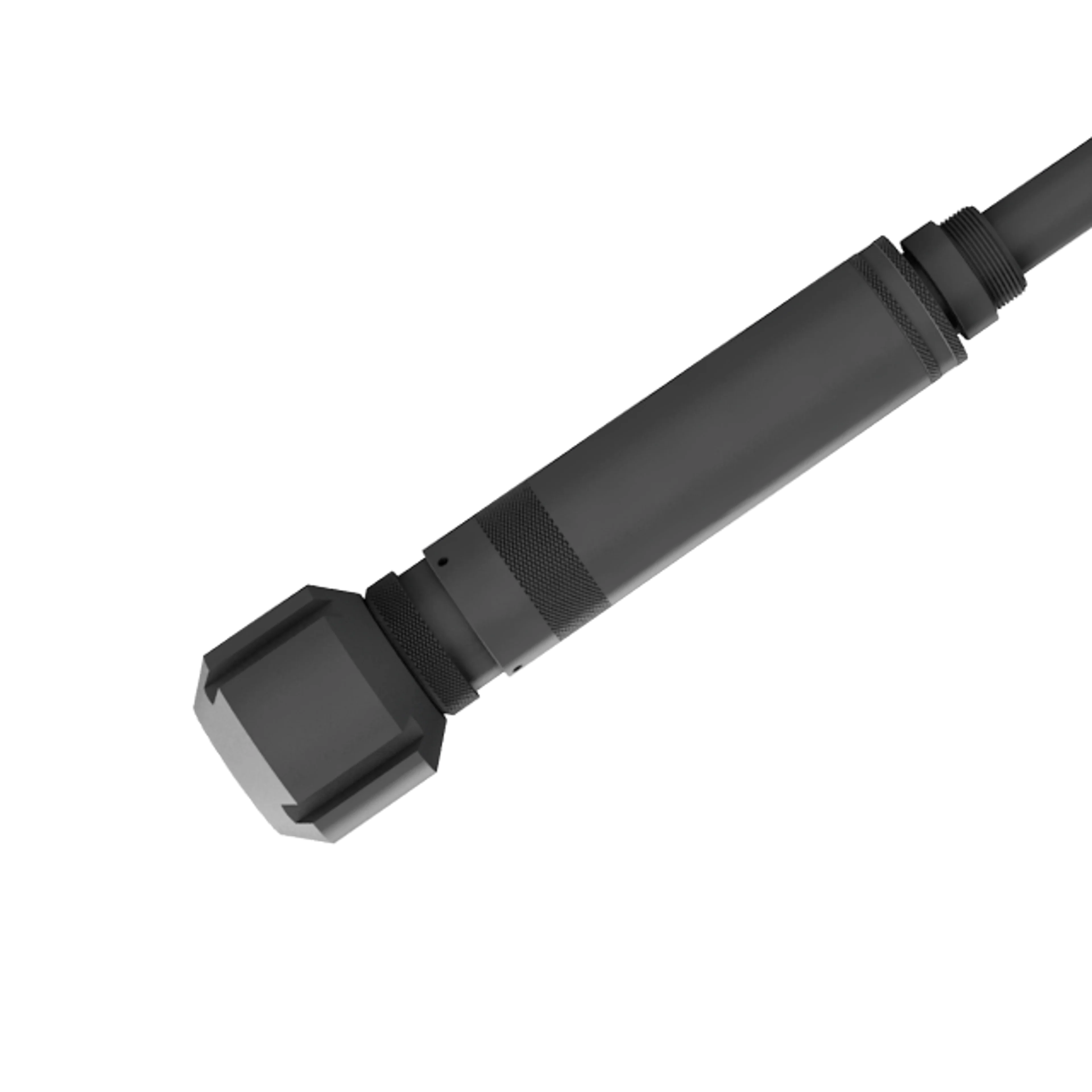

Setting Tools

Lower costs. Less time. Fewer Headaches.

Whether you’re setting tools or circulating cement, Nine offers options for doing it safer and faster.