The perfect blend of innovation, execution, and powerful equipment.

Start with our 24/7 lab and testing facilities, which develops some of the industry’s most advanced custom slurries. Follow up with advanced modeling for reservoir-tailored mud displacement and flow dynamics. Round it out with advanced equipment, like the most powerful hydraulic mixer on the U.S. market. With Nine, you’re solid.

R&D CAPABILITIES

With a state-of-the-art laboratory, fully staffed 24/7, Nine develops and tests some of the industry’s most advanced slurries to meet exacting API specifications, along with your unique challenges.

Optimal Execution

From mud displacement to flow dynamics, our teams design every element of your project using the latest modeling software. Then, we help execute that model safely, efficiently and successfully.

Slurries

Precision-engineered for flawless execution.

From lightweight, low-density formulations to advanced polymers and resins, Nine can customize a slurry to meet your basin-specific objectives.

Sealing Spacer Technology

Protect formations and optimize cementing

Nine’s sealing spacers minimize fluid loss, enhance wellbore integrity, and improve flow dynamics for efficient, reliable cementing operations.

Patriot Cementing Unit

With 1,100 hydraulic horses, the most powerful unit in America

There’s nothing like the power of unbridled productivity. The Patriot gives you faster pumping rates, reducing downtime along with risks to assets and personnel. It’s a unique combination of brute strength and intelligent engineering.

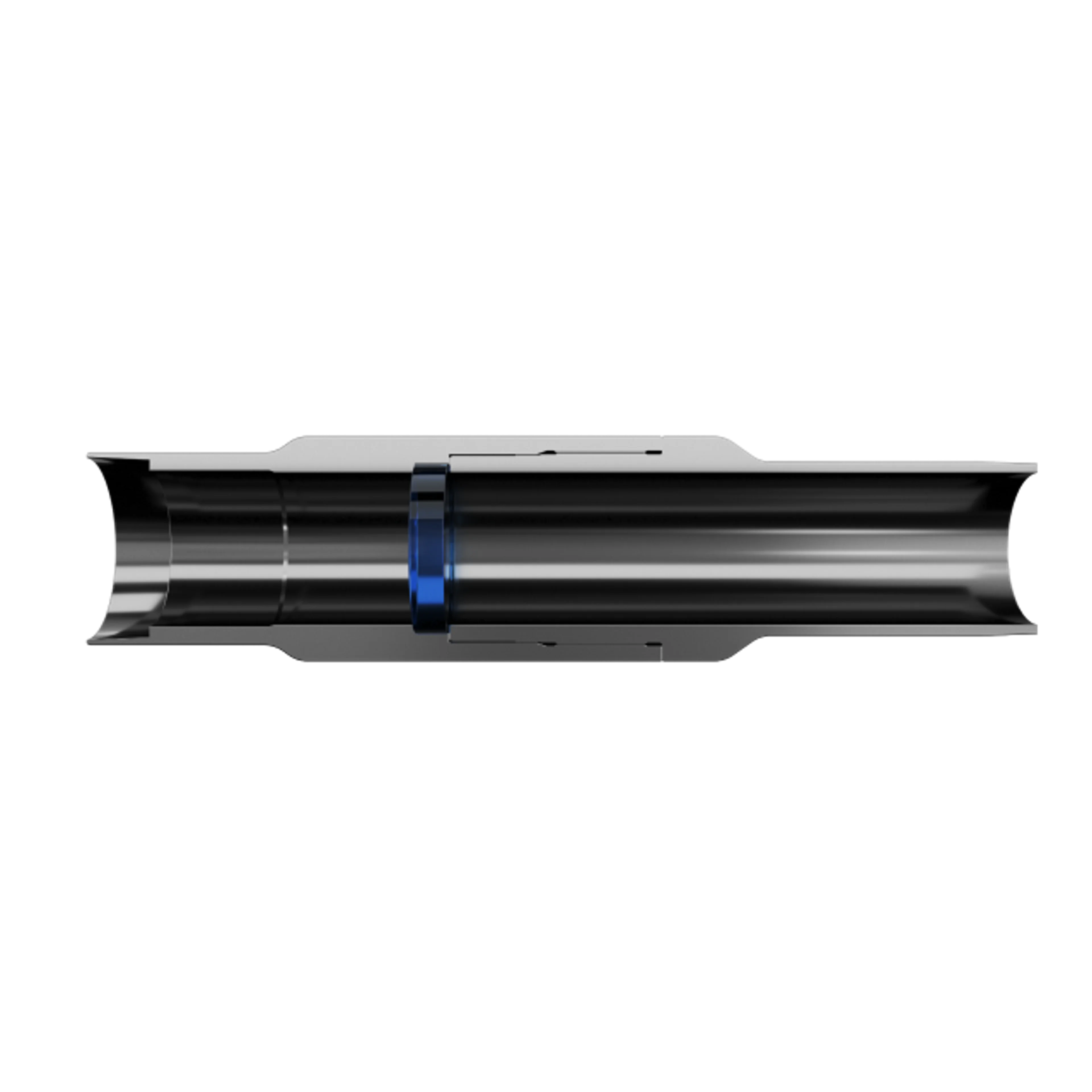

Flotation Device

Optimize your pay zone. Minimize costs.

With technologically advanced barriers for buoyancy, the flotation devices from Nine help you float your casing string across long lateral runs.

BreakThru™ Benefits

Withstands up to 10,000 psi

Easy removal by wireline or milling

Can be run in H2S or CO2