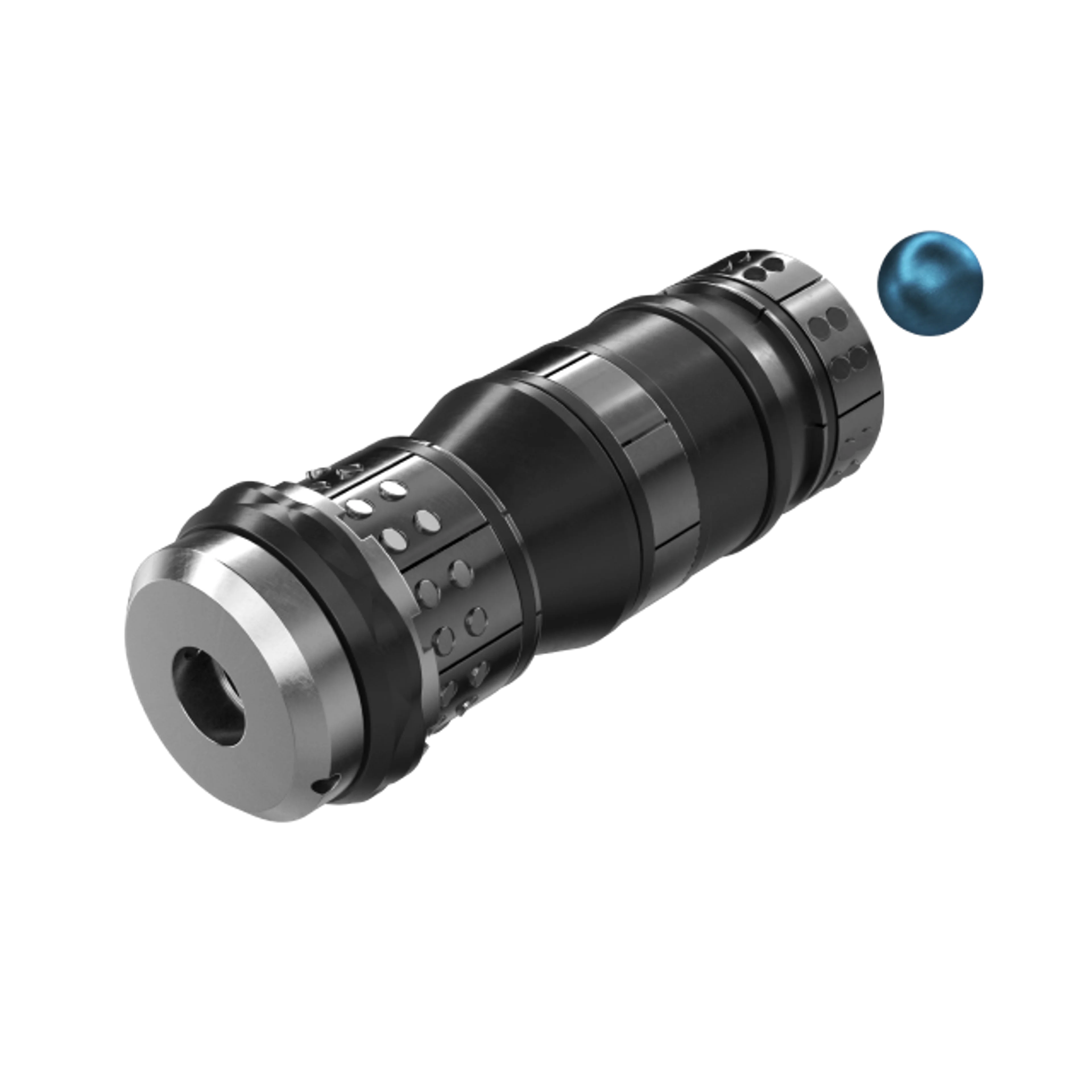

Pincer

Average millout time of

3 minutes

per plug

Goodbye NPT

With fast and effortless millout, there’s no need to pull up and replace bits to resume drilling. This accelerates overall workflow, providing considerable savings and optimal productivity.

Compact design

At 12.1” and nearly half the size of the Scorpion plug, the Pincer delivers a solid grip and swift release, with predictable dissolution and industry-leading performance.

Versatility

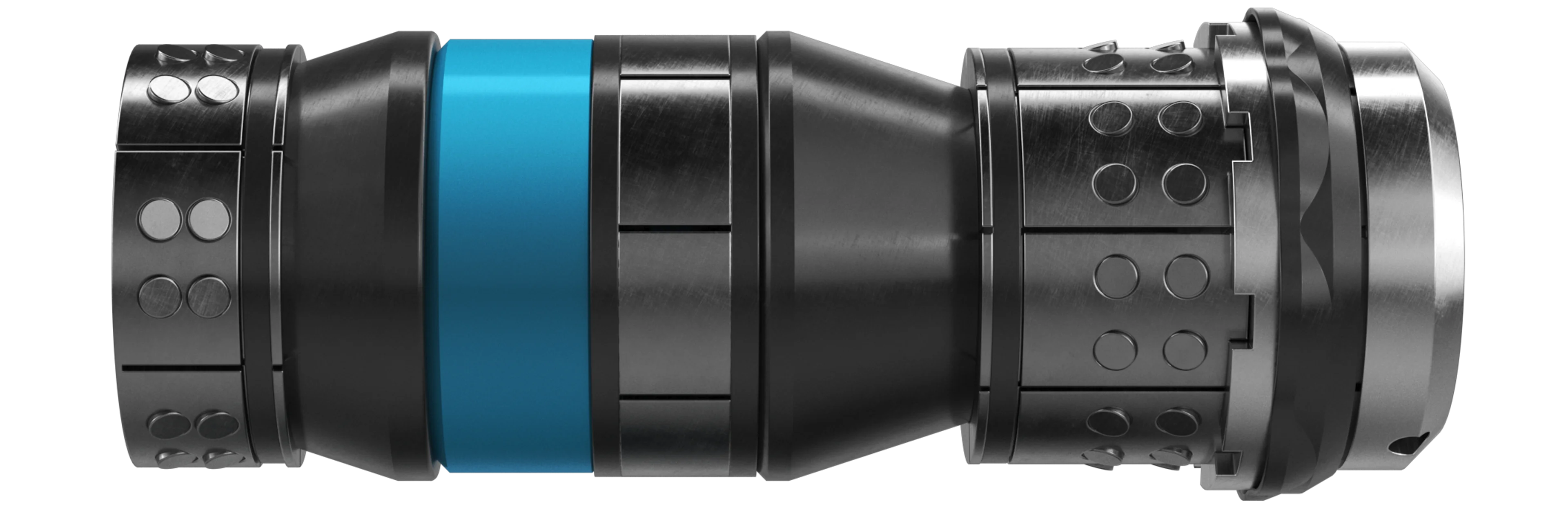

Designed to work across a range of geographic basins, wellbore temperatures and environments, the Pincer also offers ball-in-place or ball-drop capabilities, with remarkable pumpdown efficiency.

Pincer

Dig Deeper

Hyper hybrid efficiency

Enhanced efficiency with the pumpdown ring

Effective zonal wellbore isolation

47% less material than the Scorpion™

High-performance components

Compatibility and control

Tech Sheets

We're standing by